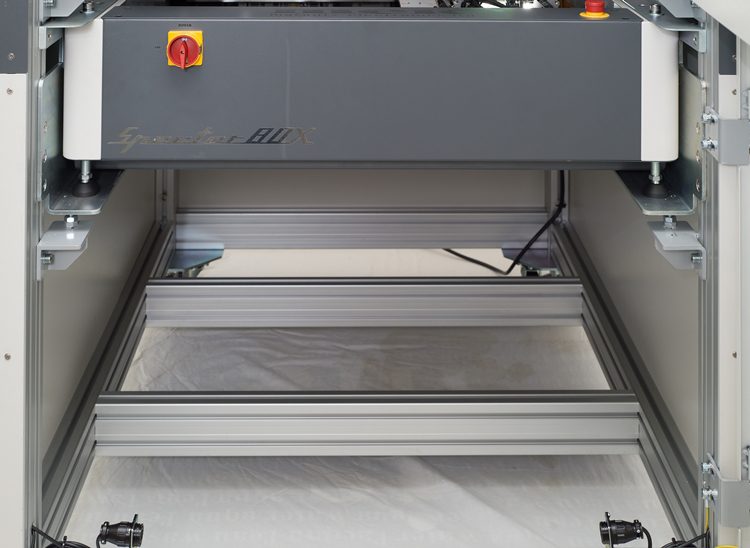

Nutek Main Frame holds 1 or 2 Mek SpectorBOX systems

Nutek Main Frame holds 1 or 2 Mek SpectorBOX systems Equipped with SpectorBOX in Top-Down inspection application with 9 camera’s and 130mm clearance

Equipped with SpectorBOX in Top-Down inspection application with 9 camera’s and 130mm clearance Adjustable width tooth belt conveyer transports assemblies up to 15kg. Equipped with optical stoppers.

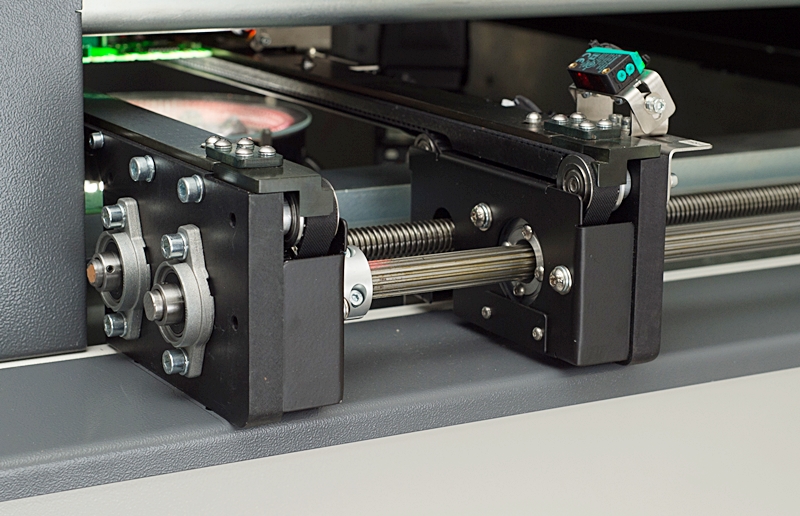

Adjustable width tooth belt conveyer transports assemblies up to 15kg. Equipped with optical stoppers. Heavy duty direct drive tooth belt motor

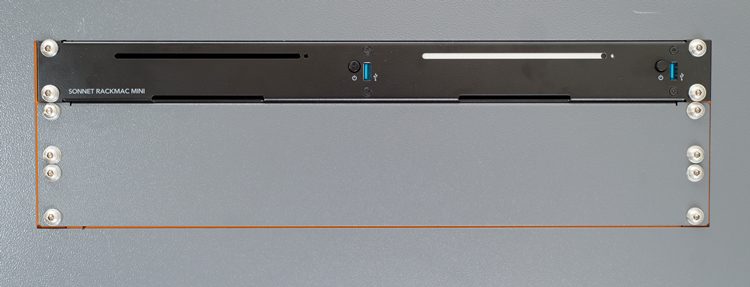

Heavy duty direct drive tooth belt motor 19” rack mount carries two Mac-PC’s for easy access PC maintenance and exchange. External power switches.

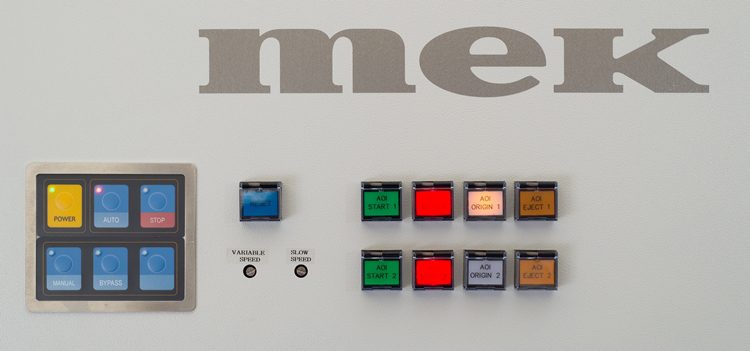

19” rack mount carries two Mac-PC’s for easy access PC maintenance and exchange. External power switches. Conveyer operation panel to select operation modes and monitor AOI status

Conveyer operation panel to select operation modes and monitor AOI status Large keyboard & mouse flap. Can carry up to 2 small wired keyboards/mice with 4 additional USB ports for flexible data exchange.

Large keyboard & mouse flap. Can carry up to 2 small wired keyboards/mice with 4 additional USB ports for flexible data exchange. Flap folds up for quick storage of keyboards and mice without the need to unplug wires etc.

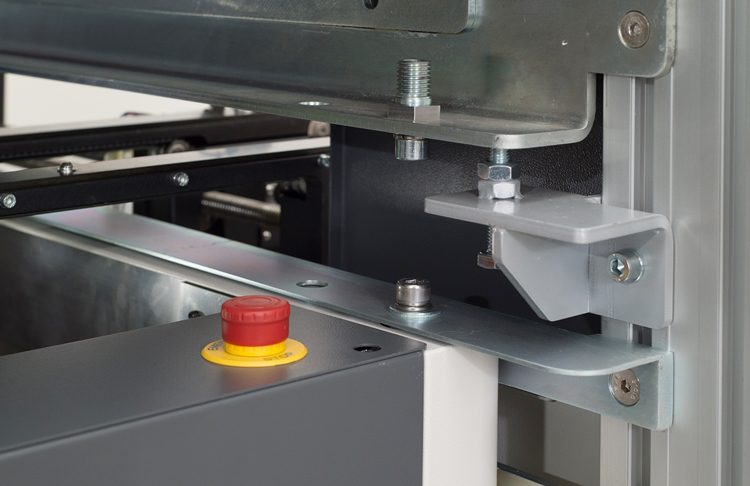

Flap folds up for quick storage of keyboards and mice without the need to unplug wires etc. Conveyer entries can be designed to customer specification with regard to size and safety features. The image shows version with width adjustment via a detachable manual crank

Conveyer entries can be designed to customer specification with regard to size and safety features. The image shows version with width adjustment via a detachable manual crank The SpectorBOX can be mounted at any height to match the conveyer height and assemblies. This is valid for both Top and Bottom inspection units.

The SpectorBOX can be mounted at any height to match the conveyer height and assemblies. This is valid for both Top and Bottom inspection units. Levelling brackets for easy adjustment of the SpectorBOX focus and conveyer height. The levelling brackets allow easy levelling by a single person, even with pre-mounted SpectorBOX systems. Built-in mm-rulers, integrated in the mainframe poles, allow easy pre-adjustment in advance of final levelling.

Levelling brackets for easy adjustment of the SpectorBOX focus and conveyer height. The levelling brackets allow easy levelling by a single person, even with pre-mounted SpectorBOX systems. Built-in mm-rulers, integrated in the mainframe poles, allow easy pre-adjustment in advance of final levelling. The top rail can hold an additional SpectorBOX for Top-Down inspection. Equipped with the same level brackets to allow easy levelling and pre-adjustment.

The top rail can hold an additional SpectorBOX for Top-Down inspection. Equipped with the same level brackets to allow easy levelling and pre-adjustment. The bottom unit can go as low as the factory floor by removing the bottom bars for inspection of solder joints from 280mm above the factory floor onwards.

The bottom unit can go as low as the factory floor by removing the bottom bars for inspection of solder joints from 280mm above the factory floor onwards. The top rail has the same adjustment options as the bottom rails.

The top rail has the same adjustment options as the bottom rails.