SpectorBOX X1

3D Modular THT AOI Solution

- 3D direct volumetric measurements of solder joints

- Pin height measurements

- Shape analysis of solder joints

- Press-Fit penetration inspection

- Effective high-gloss solder reflection suppression enhancing repeatability and reliability

- High-clearance over 100mm (3.9″) on the THT solder side for use under various conveyer systems

- 60mm Z-axis for inspecting at different heights

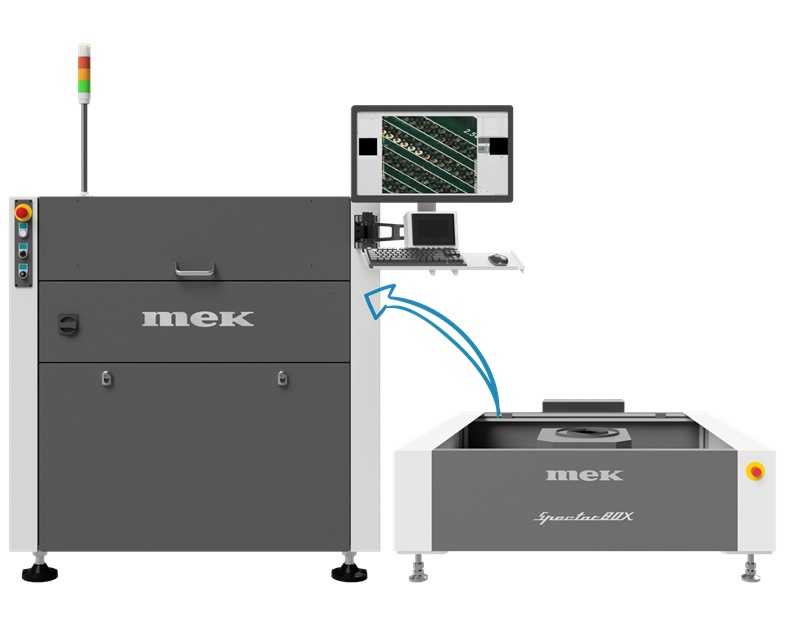

The SpectorBOX X1 delivers direct volumetric measurements of solder joints from Selective, Wave, Robotic, Pin-in-Paste Reflow, and Manual soldering systems. Drawing on Mek’s extensive experience in THT soldering measurements, this compact 3D modular AOI offers an impressive high clearance of over 100mm (3.9″) on the THT solder side, enabling comprehensive 3D THT solder joints and component inspections.

With effective shadow and high reflection suppression, along with high repeatability rates in 3D volumetric measurements, the SpectorBOX X1 redefines quality control standards, all while maintaining a highly competitive price point. Its compact design, separate control box, and I/O options make it easy to integrate into existing conveyor systems.

SpectorBOX Modular THT AOI Solution

- Designed for THT Solder Inspection of Wave, Selective, Robotic, Laser and Hand Soldered boards

- Anomaly detection for bridges, balls and foreign material

- Easy Exchangeable and Serviceable module concept

- Integrates well with custom conveyor systems for efficient inspections within solder frames

- Adopted by integrators into complex THT production lines

- Complementing Mek’s VeriSpector for Manual Assembly Guidance and Inspection

- Connects to Mek’s Catch system for handling inspection data for Repair, SPC, Monitoring, and MES communication

- Catch system runs by Win11 Platform. Managed by IT divisions outside the factory floor

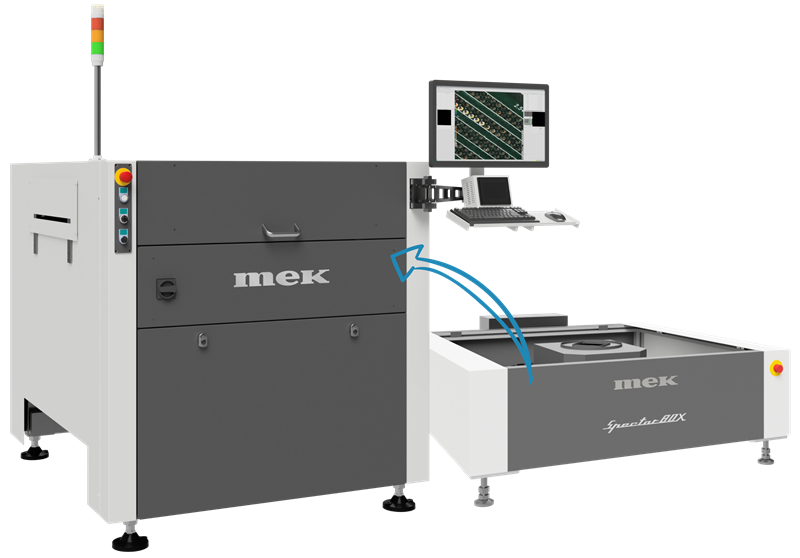

The Mek SpectorBOX modular AOI platform is expertly designed for inspecting Wave & Selective Soldering in through-hole (THT) components on Printed Circuit Boards (PCBs). It seamlessly integrates with conveyor systems, allowing for efficient inspections within solder frames.

In THT assembly lines, where custom-built solutions and handling systems for dedicated products are the norm, standard AOI machines fall short due to size, weight, clearance, and environmental conditions. Mek’s modular platform offers a customizable solution, making it adaptable to your unique production environment. Many integrators have already successfully incorporated Mek’s modular AOI into complex THT production lines.

Complementing the SpectorBOX is the Mek VeriSpector AOI, which provides manual assembly guidance and inspection, creating a comprehensive THT inspection solution for the entire assembly process. Mek’s Catch system streamlines the transfer of inspection data for repair, statistical process control (SPC), monitoring, and communication with Manufacturing Execution Systems (MES), managed by IT departments beyond the factory floor.

ROI Calculator

ROI Calculator

Calculate your AOI investment ROI in seconds. See how quickly you’ll see returns and if it’s right for your business.

Downloads

Downloads

Videos

Videos

Latest News

Latest News

Read the Latest News on our Blog: ‘Inspection Matters’