Recent new additions to our ground breaking SpectorBOX AOI system include a massive 5 inch camera clearance that enables complete single pass inspection of virtually any assembly.

Top-Down? Bottom-Up? Mek SpectorBOX AOI covers it all!

Recent new additions to our ground breaking SpectorBOX AOI system include a massive 5 inch camera clearance that enables complete single pass inspection of virtually any assembly.

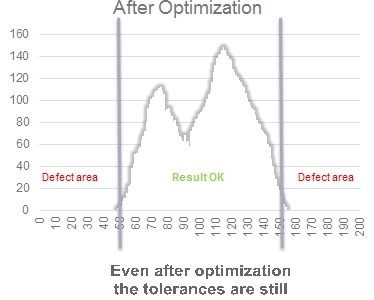

Automated pre-placement solder paste inspection (SPI) has established itself in SMT assembly as an essential tool for optimizing the electronics manufacturing process and reducing end of line defects. It’s been commonly accepted for many years that a majority of electronics assembly defects can be traced back to print defects, and by using raw measurement data from printed PCBs for volume, area, height and offset, SPC histograms and control charts can quite readily be used to… Read the full article…

AOI/SPI designer and manufacturer Mek (Marantz Electronics) recently completed a User Group Seminar in Centurion, Pretoria for a receptive group of electronics manufacturers from the region.

We’ve recently installed a fourth Mek AOI system at Projects Concern Manufacturing. The Johannesburg based EMS provider commissioned an iSpector HDL with Mek statistical control software including CS Center, Repair and Analyser. The system complements their existing 3 Mek systems.

Mek (Marantz Electronics) will be exhibiting at the Southern Manufacturing Exhibition 2015 in Farnborough in a couple of weeks with our UK distributor Gen3 Systems. The show takes place at FIVE from 10th to 12th February.

Mek (Marantz Business Electronics), has recently announced the installation of its tenth and eleventh AOI system at RH Technologies. The Israel headquartered EMS provider recently commissioned two new PowerSpector FDAz in-line AOI systems, complementing the existing 9 Mek systems.

The deployment of AOI technology for THT inspection has historically been restricted by a number of factors. These include the physical configuration of most wave and selective soldering lines, which do not lend themselves to conventionally designed AOI machines that are now popular in SMT flow lines. Product is processed in pallets moving on a continuous drive with automatic return on which the inspection must take place.

We were recently announced as AOI and SPI manufacturer of choice by GN ReSound, the component manufacturing division of GN ReSound Group, one of the world’s largest provider of hearing instruments and diagnostic audiological instrumentation. The GN Resound component manufacturing site is based in Praestoe, Denmark, and is responsible for the production of all electronic elements of the company’s products as well as 40% of the plastic parts.

Mek has appointed Minneapolis based EMSi as a US sales representative for its AOI and SPI systems. EMSi’s territory is Illinois, Indiana, Michigan, Ohio, Minnesota, Wisconsin, Iowa, Montana, North Dakota and South Dakota. The appointment follows the opening of our direct sales, marketing and applications engineering operations in the Americas, Mek Americas LLC, in March 2014.

Inline Bottom side PCB Inspection with up to 9 cameras, configurable to simultaneous Top & Bottom PCB inspection with up to 18 cameras addresses growing new needs in electronic assembly. Emerging trends in printed circuit board assembly, in particular high power automotive electronics, present an increasing requirement for automated inspection of THT. Rework is increasingly forbidden, pressurizing selective and wave soldering yields, and making AOI the solution of choice.