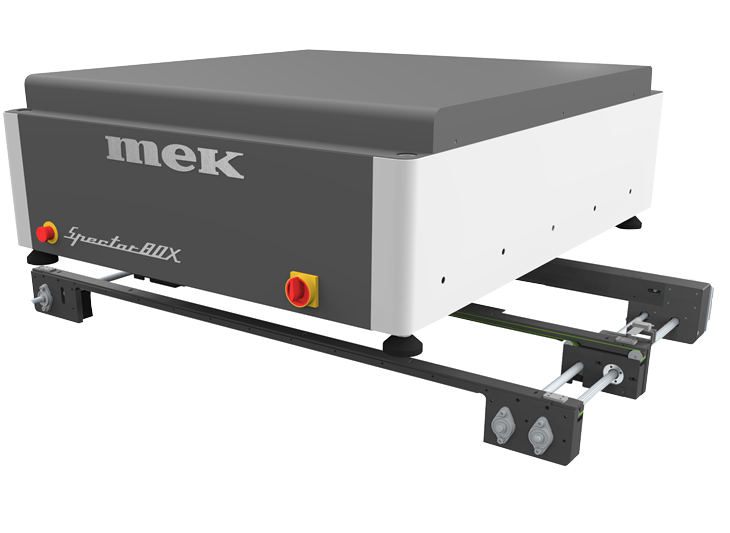

The Mek SpectorBOX modular Top-Down AOI system is optimized for the inspection of THT assemblies and inserted through hole components, designed to detect any visual defect such as component presence/absence, wrong polarity, colour, type, bent pins etc. This can be done pre-soldering or post-soldering, whether Wave or Selective soldering.

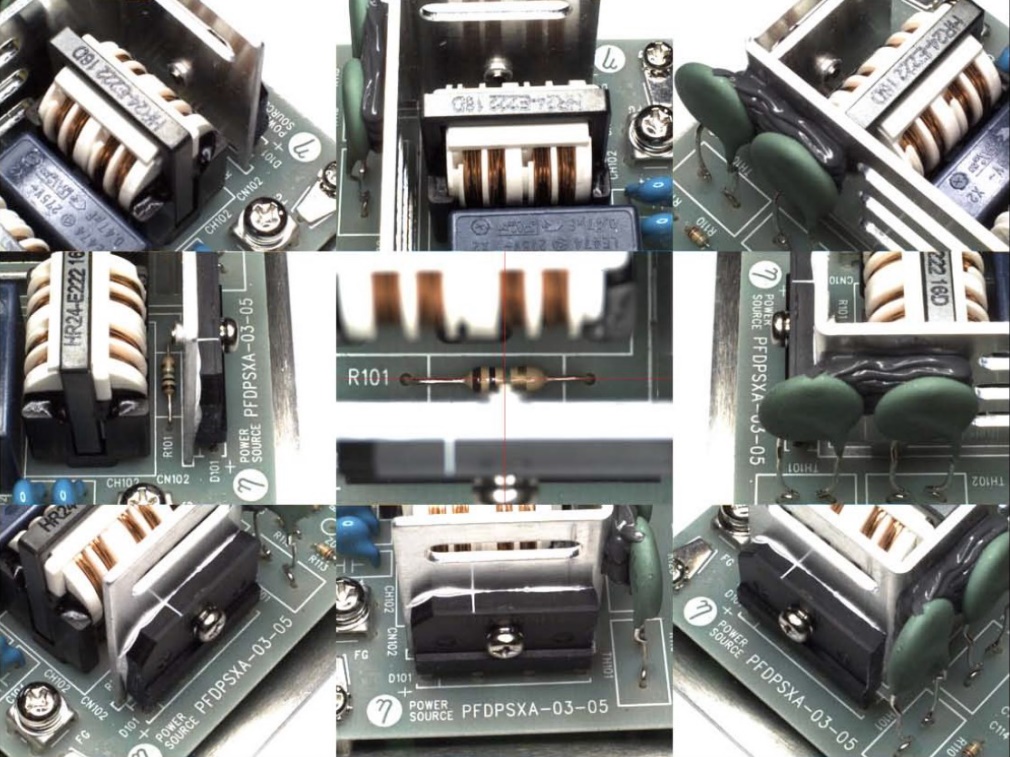

With its high resolution top camera and new & unique multiplexed 8x USB 3 Vision side camera technology, defects become visible as never before.

For the inspection of taller assemblies, the SpectorBOX Top-Down THT AOI (PTH AOI) module has a top clearance of 130mm (5.12”) in addition to an adjustable 80mm-Z-Axis. This allows a focal depth of up to 40mm for smaller features that are positioned higher than the PCB surface.

Via the GWAz head, 9-camera inspection can be achieved, even when the tallest components are present. The 8 side cameras allow inspection of features that are invisible by an orthogonal-only camera. Side marks, shadowed features and polarity indicators are now also available for inspection.

The SpectorBOX Top-Down THT AOI system is designed to inspect PCBs inside solder frames directly from the conveyor system. It can be equipped with a single Orthogonal camera (GWz) and 8 wide Field-of-View side cameras (GWAz)

Downloads

Downloads