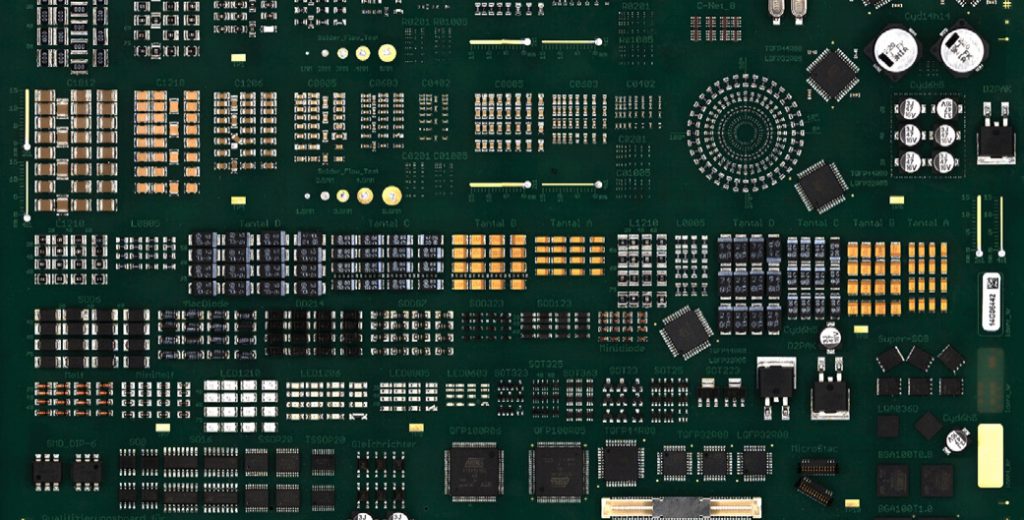

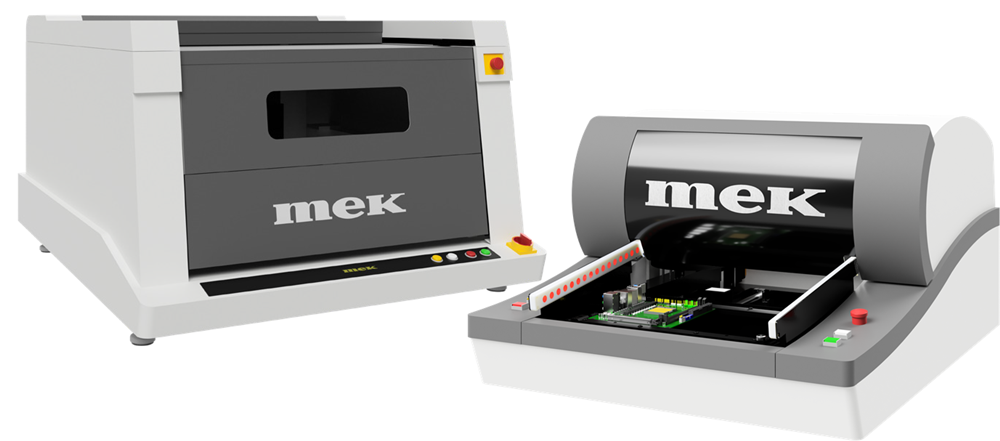

The Mek PowerSpector desktop Automated Optical Inspections system, featuring the J series inspection Head, is designed for maximum defect coverage whilst maintaining short programming times.

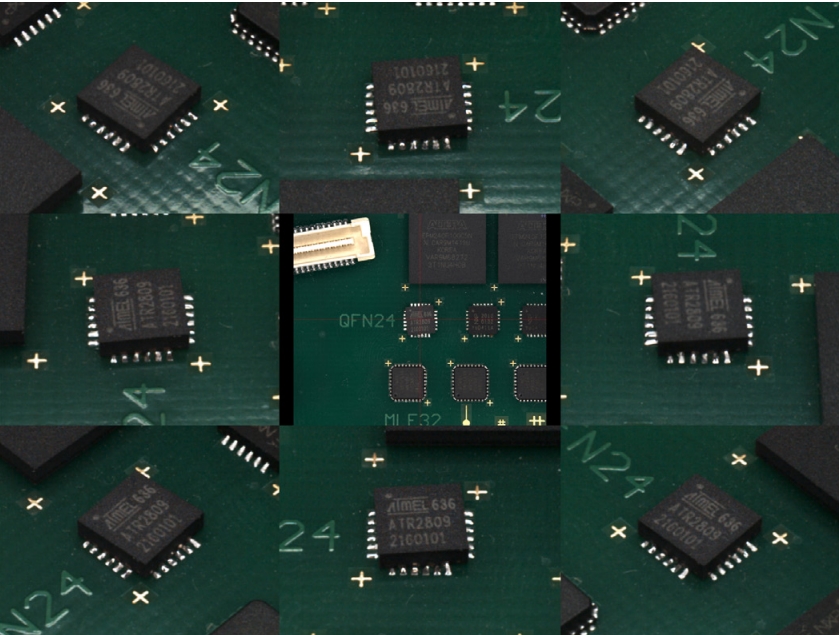

PowerSpector is the only desktop AOI machine in the market that can be equipped with 9 cameras: 1 top and 8 side cameras. For maximum flexibility, the optical unit is configurable to fit your needs today while providing upgrade possibilities for the future.

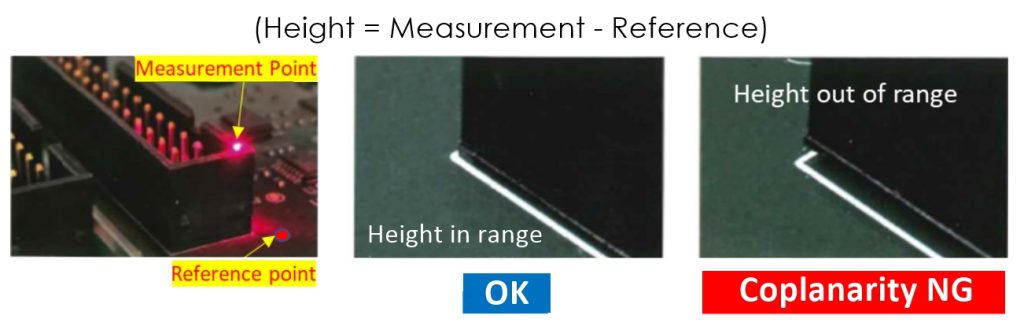

Revolutionary Selective 3D Laser Measurement Technology, allows users to conduct selective height measurements of any object with unprecedented precision. By assigning two points – a reference and a target – this technology ensures accurate and reliable measurements, setting a new standard for AOI measurement.

Quality inspection of solder joints

The PowerSpector JSAz AOI series is designed for customers for whom production quality is priority.

The JSAz series allows inspection of taller components with a Top Clearance of 60mm and side cameras with a larger Field of View and 20µm resolution. A larger 3 angle lighting system secures optimal meniscus profiling in combination with increased top clearance. In most chassis this does not sacrifice the maximum inspection area.

The inspection heads

JSAz AOI systems are the most versatile inspection engines from Mek, reliably inspecting SMT and THT component bodies for presence/absence, type, polarity, offset, text, colours etc. and components solder fillets for excessive, insufficient, no solder, shorts, lifted leads etc. Suitable for use in pre-reflow, post-reflow, post-wave and post-selective soldering, they can also be used for 2D solder paste inspection and first article inspection.

With a revolutionary Passive 3D capture technique utilizing the side cameras, 3D component images are created using all 9 cameras. The addition of a 4th white light angle on the JSAz head allows for real light side images of these 3D components.

Combining its high resolution top camera with telecentric lens and new, unique multiplexed 8x ‘USB 3 Vision’ side-camera technology, with Tilt-Shift lenses in 45/45 orientation, found defects are presented to classification and repair stations like an automatic-9 fold microscope. For the orthogonal camera a lens resolution between 10µ and 15µ per pixel can be selected, to accommodate the smallest component placed on the assembled PCB’s.

The 4 light sources with 2 different colours originating from different angles create a detailed profile of solder menisci, while the white main light results in real colour representation of components. With the DOAL (Diffused On Axis Light) that projects exactly 90⁰ on the target components, solder quality can always be inspected even when tall components are present.

The 30mm Z axis allows for compensation of warp and the ability to focus in on the tops of tall components and Sub PCBs mounted above the normal plain of the PCB.

The XY drive gantry with ball screw mechanics allows high speed inspection while maintaining high accuracy and precision. Specially coated shafts deliver quiet operation and minimal wear for lowest maintenance and calibration requirements. Several chassis with different PCB loading possibilities including direct loading and manual or automatic drawer loading with integrated automatic clamping systems. are available to create a comfortable operating environment, minimise PCB loading/unloading efforts and save time.

Mek’s process control system, the Catch System can network multiple Mek AOI machines into a completely closed loop process monitoring and quality control system uniquely optimised for each user’s workflow and internal organization.

PowerSpector platform desktop AOI systems are available sizes in M, L, and XXL with inspection areas of 350 x 250mm, 550 x 550mm and 750 x 550mm respectively.

ROI Calculator

ROI Calculator

Calculate your AOI investment ROI in seconds. See how quickly you’ll see returns and if it’s right for your business.

Downloads

Downloads

Videos

Videos

PowerSpector JSAz550 Demo

Related Products

Related Products

Latest News

Latest News

Read the Latest News on our Blog: ‘Inspection Matters’