3D measurement is the latest development trend in assembled PCB inspection. It’s creating quite a stir and it does indeed offer many advantages in terms of improved accuracy & stability of inspection results. Having quantitative data gives much tighter control than “classic” AOI and is a big step forward in improving the quality assurance and process control of assembled PCBs. Unfortunately, the term ‘Full 3D’ is often used inaccurately. Full 3D implies that the height… Read the full article…

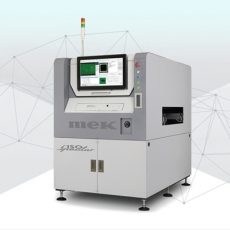

Mek’s new GTAz AOI Range Provides the Perfect Combination of 3D and 2D Inspection

New 3D topographical & imaging AOI from Mek

New entry level, low cost, desktop AOI

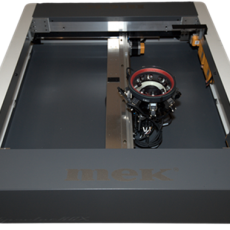

Top-Down? Bottom-Up? Mek SpectorBOX AOI covers it all!

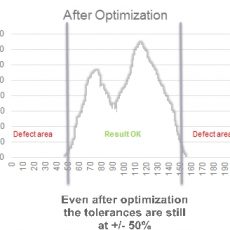

Meaningful SPI Production Control Through Automatic Normalization

Automated pre-placement solder paste inspection (SPI) has established itself in SMT assembly as an essential tool for optimizing the electronics manufacturing process and reducing end of line defects. It’s been commonly accepted for many years that a majority of electronics assembly defects can be traced back to print defects, and by using raw measurement data from printed PCBs for volume, area, height and offset, SPC histograms and control charts can quite readily be used to… Read the full article…